Prolog

Monday 4/10/2023 I received the SoCalFibershed newsletter. One of the articles was a request for volunteers to help with a one-day-1,200-sheep shearing event near Santa Ynez, California, a beautiful central-coast area ladened with native oak & walnut trees, vineyards, & thoroughbred horse ranches. The Cuyama Lamb shearing event was scheduled Thursday, 3/13, 8:30am-5:30pm. Because it's a four-hour drive from where I live, I quickly scheduled a hotel near the event for two nights. At 5:30pm Wednesday, just as I checked into the hotel, I received notice the event was pushed from Thursday to Friday, 10am. This left me with a full unplanned Thursday. Hmm, what to do. Read Meeting Mr. Leatherman to see what I came up with.

The Shearing Adventure

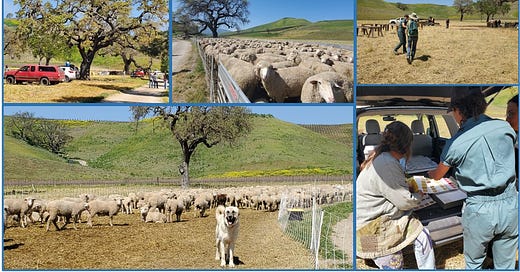

On Friday late morning, I arrived at the shearing location in the bucolic Santa Ynez area. A couple dozen Cuyama Lamb folks & volunteers had already arrived. While waiting for the shearing crew to arrive, some of us wandered around the beautiful land & went to look at the sheep that had been herded earlier into three holding pens.

Once a year, in the spring before the cheatgrass goes to seed, Cuyama Lambs hires a crew of professional shearers to sheer their roughly 1,200 head of sheep. For 3-5 months of the year shearing crews work as a team, travelling to different job sites where they shear the fiber animals, in this case, sheep.

I wanted to participate in Cuyama Lambs annual shearing because I was curious how different sheep shearing is from the alpaca shearing event I had participated in this time last year. I spent most of the day noting the differences in the shearing & fleece handling processes between the two kinds of animals. The distinctions were many. In fact, some of the few similarities I noticed were that both are sheared in the spring (though for different reasons), both rely on for-hire shearing crews & volunteers, & both the sheep & alpaca shearers shear the fiber in a pattern that allows the bulk of the fiber to easily be removed in one main piece. Almost every other part of the processes are different. Because this article is mainly about Cuyama’s sheep shearing event, only pics of this sheep shearing event are included. Here's a link to this event’s 5-minute video montage containing different parts of the Cuyama sheep shearing process. (See Alpaca Adventures "How to Shear 210 Alpacas & 1 Great Pyrenees in 2 Days" to compare to alpaca shearing for yourself!). Here are highlights of the differences between sheep shearing & alpaca shearing I noticed.

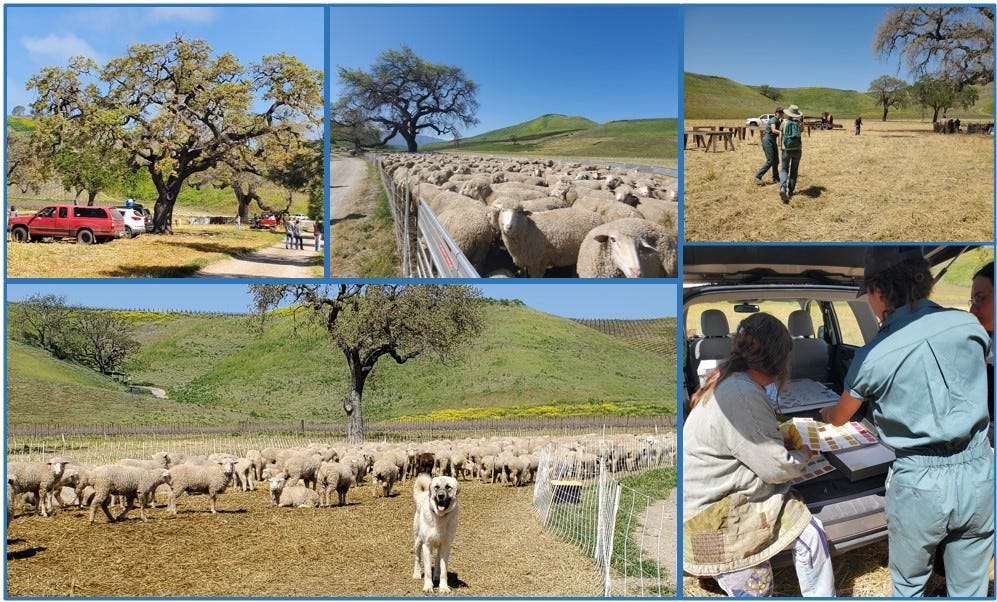

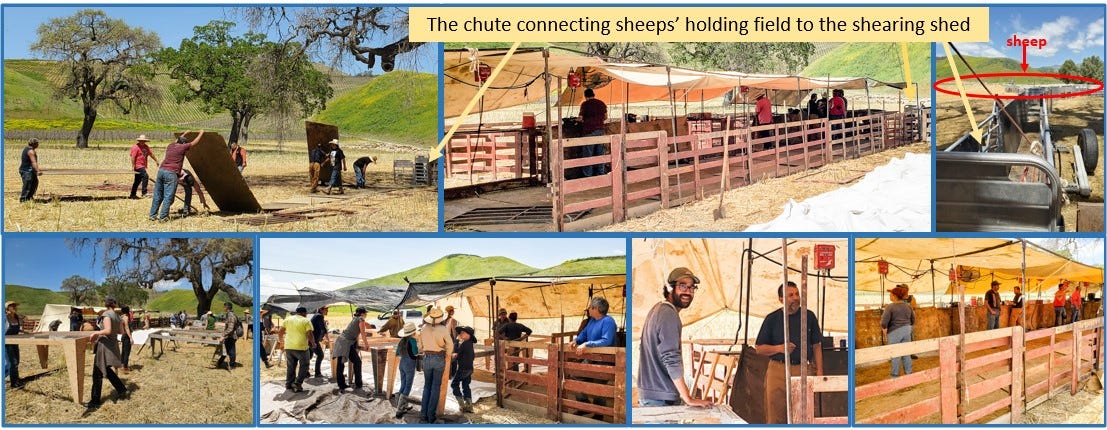

Shearing Shed Setup

For sheep, a temporary shearing shed was constructed in about an hour. It included sheets of plywood flooring, a small, fenced-in shearing corral, & six generator-run shearing stations. A half-height fabric "wall" was hung behind each station. On the other side of each fabric "wall" was a small holding pen that looked like it could hold between 8-10 sheep.

On one end of the fenced & gated shearing shed was a chute used to move the sheep - single file - from one of the nearby fields into the shearing shed. The field crew & volunteers made sure the chute was full at all times.

Other volunteers moved the shorn fleece from the shed onto the skirting tables. There was continuous movement from the field into & out of the shearing shed.

On the opposite end of the shed, several skirting tables were set up just outside of the shed. Tarps were laid under the tables to collect the skirted (discarded) fibers.

At the Alpaca shearing event I participated in last year a permanent barn was configured with two mats:

One mat was used to trim toenails, grind teeth, & inject annual vaccines & otherwise prep the alpaca for the shearer.

The other mat was used to perform the shearing & collect & package the animal's sheared fleece.

Standard fleece collection kits were prepared ahead of time to collect each alpaca's fiber. Each kit included a wax paper "noodle" used to collect & roll up the prime fleece (called the blanket), a smaller plastic bag to collect the secondary fleece (from the necks), a large plastic bag to contain both, plus the loose lesser quality fleece, and name tags to adhere to the blanket noodle, the 2nds bag, & the larger bag.

The next station included a scale to weigh & record each blanket & total fiber, plus the weight of the post-shorn alpaca.

Getting Animal To, In, & Out of the Shearing Shed

Sheep are constantly herded - single file - from an adjacent (temporary) field into the chute that constantly feeds sheep into the shearing shed 2-3 dozen at a time. Sheep are sheared several at a time. In this case, 6 shearing stations were set up in the shearing shed.

Alpacas are herded from their fenced "home" field, a field at a time. Most fields held between 20-25 alpacas. Temporary fencing is arranged like a large funnel guiding the alpacas from their field, down the road, & into small holding pens adjacent to the barn/shearing shed, which can hold 4-8 alpacas. Once in the holding pens, they are haltered & led to the shearing barn one at a time. There, the alpaca is led to an empty mat at the front of the barn. When the shearing process is done, each alpaca is led to a slightly larger holding pen outside the back of the barn/shearing shed where its halter & lead rope are removed. Once all alpacas from that one field are done, they are herded as a group back to their original field.

Let the Shearing Begin!

Once the sheep shearing shed was packed full of 20-30 sheep, each shearer grabs a sheep, rolls it onto its behind, puts at least one leg behind his, the shearer's, leg. This holds the docile sheep still until the shearer completes his work.

Shearers clip the wool in a pattern - close to hide - so that fleece is removed in one piece, being careful to nick the skin as little as possible.

Once a sheep was shorn, the shearer pushes the sheep through the fabric wall into the holding pen & grabs another sheep in front of him. Another crew member is assigned to monitor & manage the smaller pens holding the shorn sheep. S/He periodically counts how many sheep have been sheared by each shearer before releasing the shorn sheep into a larger field, thus emptying the holding pen only to have the holding pens fill up with the next batch of newly shorn sheep. Part of each shearer's pay is based on how many sheep he shears.

Fiber Collection, Skirting & Sorting

Shearing is only part of the job. It's important to the herd owners how the wool is prepared from the time it leaves the sheep to the time it gets to the bale. Knowledgeable shed & skirting staff are important.

Trained crew members gathered each sheep's fleece in whole & move it from the shearing station immediately after the sheep is shorn to one of the many skirting tables adjacent to the shearing shed. There the fleece is skillfully unrolled in atop the table in a movement similar to tossing pizza dough.

On the skirting table, volunteers pick through the fleece to remove vegetative, manure, & other materials embedded in the fleece. Any fleece removed during skirting is dropped onto tarps under the skirting tables. At the end of the day, the discards are gathered for use as compost & other things.

Once skirted another volunteer rolls up the skirted fleece from the table & takes & loads it into a baling machine containing the other sheeps' fibers.

Upper pics from left. A fleece being moved from the shed to one of the skirting tables. Many volunteers make quick work of skirting the wool. Bottom left & center pics. Jenya (Cuyama Lambs co-founder, in green top & baseball cap) gives volunteers skirting tips. Bottom right. Another Fleece was just added to the baling machine. See Jenya give skirting tips at video timestamp 04.47.27)

The baling machine operator frequently presses the fleece down into a cube, which is packed and loaded onto a truck. Each bale of wool weighs 400 to 500 pounds. Each sheep produces between 10 and 20 pounds of wool. That weight is considered the “grease weight,” and drops by about half once it’s scoured/cleaned due to the removal of lanolin during the process. Baling all 1,200 sheeps’ fleeces in the same bales is possible as this breed is all the same color & texture.

Each Alpaca's fibers are gathered & packaged in the shearing shed as it is sheared. The blanket fiber (prime fiber called 1sts) is wrapped into a wax paper 'noodle' as it comes off of each alpaca. The neck fiber (called "2nds) is put into a smaller bag, & the haunch & legs (called 3rds) are left loose. All are then put in a larger bag & stored for sorting & skirting another time. Each alpaca produces between 3-8 pounds of fiber. Because alpaca fiber contains no lanolin, its weight is reduced only slightly depending on how much fiber is discarded during the scouring/cleaning process.

Post-Shearing Holding Pens & Release

Sheep holding pens are set up per shearing station & used for counting the number of sheep shorn per shearer. Once the holding pens fill with the sheared sheep, they are counted & let out to frolic bare skinned into a large field surrounded by temporary electric fences.

For Alpacas, a large holding pen adjacent to the back of the barn is used to contain a field's post-shorn Alpaca group. Once all alpacas from the group are shorn, they are herded together back to their home field.

Though not officially part of the shearing process another thing I noticed was that tending to sheep requires two kinds of dogs: herding dogs & guardian dogs. Alpacas, on the other hand, need only guardian dogs, as they are typically not left to roam outside of fenced fields, seeming more domesticated. An alpaca rancher usually knows each alpaca by name, whereas I don't get the impression sheep are named or individually identified by their owner/s.

Epilog

About Cuyama Lamb

Cuyama Lambs truck their sheep to the seasonal grazing spots as contracted with the landowners. The sheep help regenerate the native California Central Coast grasslands & provide trusted, production of sustainable, ethically raised food & fiber. They achieve this through offering fire mitigation grazing, integrated crop management, & ecological restoration services throughout California. Other products they produce are fresh, sustainably harvested lamb meat, & sustainably produced roving & yarn.

The Sheep Shearing Profession & Job Market

I was also curious about the shearers. Shearing crews usually spend 2-3 days at each site, travelling from site-to-site, for 3-6 months - usually spring - during the year. I noticed the travelling sheep shearing crew looked to be in their 40s at least, whereas the alpaca shearers I met were in their 20s & early 30s. One of the sheep shearers mentioned he was a 3rd-generation shearer - an impressive legacy! Here are some things I learned about what it takes to be a professional shearer.

Each shearer shears between 50-60 sheep a day. Working 8 hours, that's one sheep every 10-12 minutes!

Besides just shearing, shearers setup and tear down of mobile shearing shed, help move sheep in and out of shearing shed; maintain and repair equipment used in shearing to the standard established by the employer.

As with many professions, there is a continuous need for young sheep shearers as the older generation retires & the sheep populations grow. The best ways to learn shearing is to become a shearing assistant. Though certification is not necessary, being certified can make it easier to find work according to the American Sheep Industry Association (ASI) who handle formal training and certification in sheep shearing.

While there is always a strong demand for skilled shearers, some operators are still reluctance to put "learners" on the boards. According to Peter McCrabb, a member of NSW Farmers’ Wool Committee, "there are a lot of contractors and sheep owners who [haven’t] used a learner for the past 15 years. This has contributed to a shortage of quality shearers . . . they have to get together to ensure there’s a continuity of work for young people coming into the industry.”

Bringing in new generations of shearers faces additional challenges.

It's hard, physical work which apparently US citizens are reluctant to pursue. This strikes me as so very odd.

A sheep shearer is paid similar to warehouse, slaughterhouse, & other essential service workers. Many of those jobs are inside, under florescent lights, with poor working conditions & air quality.

Whereas shearing is in the great outdoors in natural light, shearers get to travel & see beautiful parts of the country, & is very physical. Some studies show a shearer expends as much energy in a working day as a marathon runner (no gym membership needed!).

Being away from family & community for long stretches is challenging. For some, lack of internet access on the properties they work on breaks their family & community bonds down even further. While this is understandable, today's cell & internet services are rarely more than a few hours away. Younger shearers are more likely to feel disconnected as they've grown up with constant, instantaneous online contact whenever & wherever they go.

But within the Fibershed movement in California, things seem to be shifting, as there is growing interest among younger adults in shepherding & shearing sheep. Read Fibershed.org’s 3-Part Series: Shedding Light on Sheep Shearing - for Understanding the Shearing Process

Stay tuned to Fibershed.org, SoCalFibershed.org, & subscribe to Bev-Sue’s Fibershed Adventures to join the adventures!